环保处理系统Environment Protection System

打造了生态养殖环境

DEXING has spent heavily building up an ecological environment of breeding

| 德兴污水处理采用两道系统模式:在各养猪场因地制宜的配套了不同工艺的环保处理设施,实现粪污资源利用和水资源循环利用的有机配合。第一方案,粪污无害化处理和资源化利用。采用主体工艺为:固体分离还田利用>黑膜沼气池+沼气发电>沼液暂存池>沼液ER均质池>还田利用,实现资源化利用。第二方案,工业化污水处理循环利用。采用主体工艺为:固体分离还田利用>气浮装置>叠螺离干机>动态好氧池+沉淀>反渗透水处理系统,实现水资源循环再利用。 | 公司以实施农牧结合,种养结合“四位一体”循环农业生态经济生产方式.以沼气为纽带建立起多个物种共栖,智能多级利用的物质循环利用型生态农业模式。实现猪场废弃物无害化处理,粪污资源化循环利用,最终实现零排放。真正走生态健康养殖之路,保障农村公共卫生环境,达到良好的社会与环境效益。 |

| There are 2 distinctive systems used in DEXING for sewage disposal: in deferent farms of DEXING, different environmental protection approaches are adopted for 2 objectives, manure recycling and water recycling. Solution no. 1, manure processed and recycled to be fertilizer for clops use. Solution no. 2, the sewage is treated by going through different techniques including air flotation, stacking and dehydrating, after going through the last step of reverse osmosis, the water is as clear as it can be used in pen cleaning, greening irrigation and aquaculture. | DEXING combines agriculture with animal husbandry, planting and breeding, the “FOUR IN ONE”, a pattern of recycling agricultural eco-economic mode of production. It realizes Hazard-free treatment of waste, manure recycling,ultimately achieves zero emissions. The path of healthy ecological farming gives the rural public a healthy and fresh environment, which are set as the industry benchmark by the provincial authorities. |

处理工序 Steps:粪水引进集水池,达一定液位时,搅拌器与潜污泵自动启动,污水经管道进入经过四个阶段的处理工序。The fecal sewage is collected, the mixer and submersible pump starts as per set, going through 4 steps.

① 预处理-固液分离 Pre-treatment:通过固体分离将粪渣挤压脱水成固体,还田利用。粪水进入沼气池,沼气用于发电,沼液作为肥料资源利用,多余的进入工业模式,提供生产用水再循环利用。Solid-liquid separation] Separating fecal in from the liquid, dehydrate into solid fecal to be used in farming. The remaining liquid enters the methane tank, to generate biogas. The biogas slurry is then recycled for farming. The extra is fed into the air floating process, to realize the water filtration and recycling purpose.

②气浮工艺-固液深度分离 Air flotation:通过数以亿计气泡张力作用分离粪水中的悬浮物;分离开的黑色悬浊液体,在PAC&PAM的共同作用下,将水中的固体悬浮小颗粒SS撇出,使其降到国家排放标准。In-depth Solid-liquid separation] The suspended solids in manure are separated by functioning tension of hundreds of millions of bubbles; With the help of PAC&PAM, the suspending small particles SS is then removed from the black sewage. The remaining water meets national emission standards.

③气浮叠螺工艺-污泥脱水 Stacking Sludge dehydrating:气浮后污泥含水量在96%-99%之间。在PAM的作用下,污泥中的SS絮凝成团,在叠螺机的作用下被挤压螺旋增压呈饼状(含水率70-80%)排出,利用还田,挤出的水重新注入气浮机。The percentage of water of the sludge after flotation is between 96% and 99%. With the function of PAM, the SS flocculation clusters. The stacking machine squeezes the water out and turn it into cake-shape (containing 70-80% water), used as fertilizer, the extrude-water is re-injected into the air flotation process.

④反渗透-清水交付 Reverse osmosis-Clear water result:利用超分子纳米复合膜,将气浮后污水进行层层过滤,去除其中的重金属、细菌、色素、SS、部分氨氮,使出水水质清澈见底,可用于猪舍冲栏,绿化灌溉,水产养殖,真正实现零排放!With the use of supramolecular nanocomposite membrane, the sewage goes through layers of filtration after air flotation, while the heavy metals, bacteria, pigments, SS, part of the ammonia nitrogen are removed afterwards, so that the water is crystal clear, which can be used for pig pen cleansing, green irrigation and aquaculture, actually achieving zero emissions!

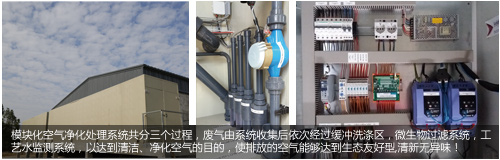

猪场空气净化系统

Airwasher System

The modular air purifying system consists of 3 steps. The exhaust-gas will be collected and go through the buffer washing zone, the microbial filtration system and the processed-water monitoring system, from which the exhaust-gas is cleaned and purified, fresh and friendly to the environment.

上海德牧成功打造模块化、自动化的粪污环保处理系统

通过节水型猪舍的设计,粪水深度分离,气浮叠螺工艺,反渗透生物水处理等技术,实现水循环利用零排放模式。

Shanghai DEMU develops the modularized automatic Manure Treatment System: through the design of water-saving pig house, solid-liquid separation, stack screw process, reverse osmosis biological water treatment technology, water recycling to achieve zero emission mode.